Our Projects

Our distinctive strength is our capacity to internally supervise and control the entire project, guaranteeing quality and efficiency throughout, while minimizing both downtime and expenses. We handle the complete process, from concept to installation.

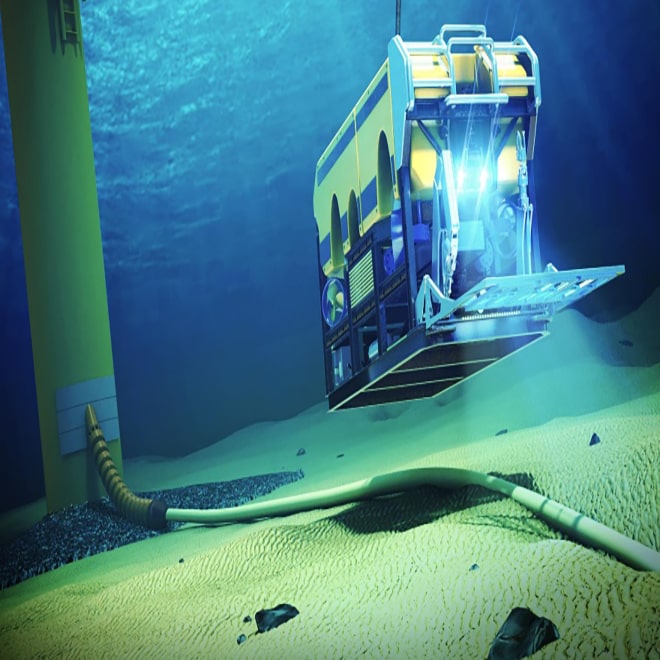

Inspection by ROV

ACAMARINE researchers are spearheading the development of an autonomous robot designed to detect potential leaks and structural issues in subsea pipelines, aiming to address the rising number of severe accidents within the global oil and gas industry. This transformative technology promises to significantly enhance the safety and cost-effectiveness of subsea inspections, ultimately safeguarding subsea environments from potential disasters.

The Yumna field, formerly known as the GA South field, stands as the pioneering offshore oil field development situated in the Gulf of Masirah, Oman, marking a significant milestone as the first offshore oil field discovery in eastern Oman. This strategic endeavor aligns with the urgent need for timely subsea infrastructure inspection, particularly of pipelines and offshore wells, to prevent oil spills and related environmental damage, which are unfortunately all too common in Oman’s waters.

Vessel repairing

The oil product tanker vessel EMIRATES NADA II sustained steel damage to its side shell while at anchorage. The vessel’s owners enlisted our company Ltd for the necessary repairs. Given the vessel’s ongoing operations and a scheduled stop in EMIRATES NADA IIX, our repair team put forth a proposal based on a crew-compiled report with accompanying imagery. Subsequently, the vessel arrived at the EMIRATES NADA II anchorage on November 9, 2020, for steel renewal. A team of 10 technicians, equipped with all necessary materials and tools, was promptly mobilized on the same day to commence the repairs, with the entire project slated for completion within one week.

Following a joint inspection onboard, additional steel renewal work was identified. Despite the vessel’s tight schedule, it was imperative to address the additional repairs within the initially agreed-upon timeframe. After discussions between the repair’s supervisor and the vessel’s technical fleet manager, a consensus was reached to proceed with the supplementary tasks within the original one-week schedule.

Additional resources were promptly coordinated, facilitating the completion of the entirety of the work within the agreed time frame. The client expressed high satisfaction with the repair team, noting the timely completion of work, exceptional results, and superior adherence to health, safety, and environmental (HSE) protocols as “more than excellent.”